July 23, 2025 Industry news

Digital Product Passports (DPP) form part of the EU’s Ecodesign for Sustainable Products Regulation. From 2027 the first wave of industries such as textiles, construction, electronics and batteries will need to attach a digital record to every item. This record must show where a product was made, which materials were used, what its environmental impact is and the journey it takes through the supply chain. By 2030 all other sectors will fall under the same rules.

The aim is to boost transparency for regulators, businesses and consumers. It supports net zero goals by encouraging reuse and recycling and makes it easier to track a product from source to shelf. But the regulation is not optional. It is a legal requirement and without a compliant passport shipments will be stopped at the border.

The scale of the risk

Our latest research at GS1 UK shows only 16 per cent of UK exporters feel fully prepared.

79 per cent worry they could be prevented from trading with the EU if they fail to comply.

One third of those we spoke to said they would not survive losing access to what remains a 300 billion pound market for British goods.

Textile firms already know what this feels like. Since 2019 exports from our textile sector to the EU have fallen by 63 per cent.

Brexit and new transparency demands have combined to challenge long standing trading relationships. Now the arrival of Digital Product Passports threatens to increase that pressure unless businesses move quickly to understand and meet the new requirements.

Turning regulation into advantage

Digital Product Passports may begin life as a compliance obligation but they also open the door to real business opportunity. In our New Era of Transparency report 94 per cent of UK firms told us transparency is critical to future success. Consumers agree. 81 per cent say that detailed product information influences their purchasing decisions and 60 per cent say they would trust a brand more if it offered verifiable sustainability data.

By embracing passports early businesses can build stronger reputations and deepen customer loyalty. They can use passport data to demonstrate environmental credentials in every campaign and unlock circular economy models that support resale, repair and remanufacture. And within high value sectors passports act as a digital seal of authenticity to help combat counterfeit goods.

Loake Shoemakers: preparing with QR codes powered by GS1

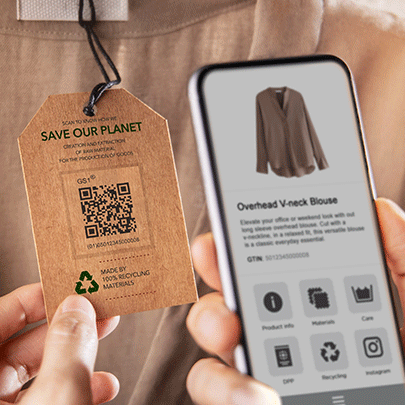

Loake Shoemakers, a fifth‑generation family business in Northamptonshire, has embraced Digital Product Passports by embedding QR codes powered by GS1 into each of its products. Faced with the EU’s forthcoming requirement for detailed digital records on origin, materials, sustainability credentials and care guidance, Loake partnered with Buyerdock to automate the process.

Each shoe now carries a unique QR code that links to a dynamic landing page, seamlessly updated from Loake’s product information system, ensuring full compliance with the 2027 regulations without disrupting production or compromising craftsmanship.

This approach has delivered tangible benefits: it has cut manual data‑entry tasks, improved accuracy and enhanced customer engagement, while also future‑proofing Loake against evolving EU sustainability rules. Customers can scan a pair of shoes to learn about leather provenance, environmental initiatives and proper disposal, reinforcing brand trust and loyalty. As Loake explores woven labels and a loyalty app built around its QR codes, it is setting a benchmark for transparency and circular business models in the footwear industry.

Overcoming common barriers

We know that many exporters face genuine hurdles as they work towards compliance. Our research reveals that data standardisation is the biggest concern, cited by 36 per cent of firms. Implementation costs worry 31 per cent and 28 per cent say integrating new requirements into existing systems is their greatest challenge.

To help members through this transition we offer global product identifiers that guarantee consistent identification, data pool services to create accurate and shareable records and QR codes powered by GS1 to host passport information. Today 29 per cent of brands already use QR codes for product data and a further 53per cent are considering adoption to meet EU rules.

A collaborative call to action

Many UK exporters cannot prepare for Digital Product Passports through their own efforts alone. Unlike their European counterparts, who have benefited from dedicated funding and technical support, UK firms have received no equivalent assistance to help them meet the detailed data‑management and reporting requirements. This lack of support leaves many businesses at risk of non‑compliance, with potential border holds, lost revenue and damaged customer trust.

GS1 UK is therefore calling on government to provide practical assistance and clear guidance on DPP compliance. By working with industry to offer advice, share best practice and clarify technical expectations, we can help UK businesses build the foundations they need to succeed in the EU market and beyond.

The clock is ticking and businesses need to get their data in order, or risk being locked out of a £300 billion export market. While GS1 UK can provide the technology and standards needed to comply, including smart-QR codes that can host Digital Product Passports, more urgent action is needed. Businesses must act now to prepare."

Anne Godfrey

CEO, GS1 UK

Next steps for UK exporters

Time is short but the path is clear. We recommend that every exporter begins by auditing product data against GS1 global standards to identify gaps. They should then form a dedicated team to drive readiness, pilot QR codes powered by GS1 on a key product line and engage GS1 UK for workshops, toolkits and expert support.

Product data can become more than a compliance requirement. It can become a passport to growth, trust and sustainability.