March 17, 2025 Industry news

The construction industry is at a turning point. For too long, inefficiencies and fragmented collaboration have slowed progress. But digitalisation is shaking things up as organisations across the sector integrate new digital technologies, creating a smarter, more connected industry.

At the forefront of this transformation are GS1 UK standards—bringing interoperability, transparency and efficiency to the built environment. A recent example of how GS1 standards are powering progress in construction can be found in the 2024 Old Newton School project which serves as proof that when trusted data and technology come together, real change happens.

The challenge

Old Newton Primary School needed a new classroom built to ambitious sustainability goals. A key driver was ensuring excellent indoor air quality, free from Volatile Organic Compounds (VOCs) and other contaminants, while also providing a long-lasting, flexible teaching space.

Traditional and prefabricated methods were dismissed due to design limits, durability concerns, and air quality risks from petrochemical materials. Instead, a digital strategy was developed to enhance collaboration between designers, manufacturers and builders.

The school needed a solution that would track and manage trusted data across the entire building lifecycle. Traditional methods—where information is scattered, inconsistent, and difficult to access—just wouldn’t cut it. The challenge was clear: create a system where NBS products would be uniquely identified, trackable and accessible in real time.

This was achieved thanks to a pioneering partnership between Natural Building Systems, Circuland, OrcaScan and GS1 UK.

Each partner brought a unique expertise to the table. Natural Building Systems provided the sustainable, non-toxic materials needed for a healthy learning environment.

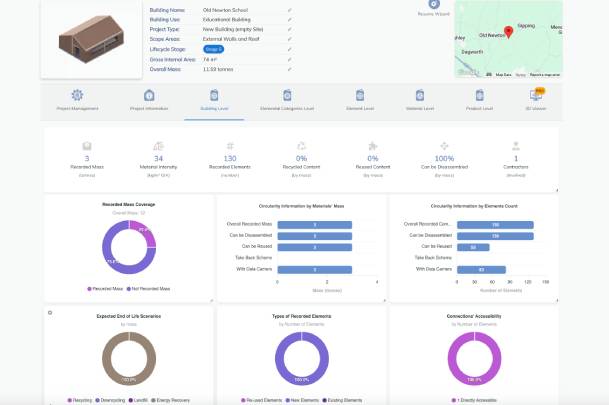

Circuland powered the Digital Product Passports (DPPs), ensuring that materials had structured, accessible lifecycle data.

OrcaScan enabled seamless on-site tracking through GS1 powered QR codes, bridging the gap between digital records and physical assets.

GS1 UK provided the Global Trade Item Numbers (GTINs)—the foundation for standardised, interoperable data-sharing across all systems.

Together, these partners set out to make construction smarter, greener, and more efficient through a project that would not only to meet sustainability targets, but also to establish a replicable model for digital innovation in construction.

The solution

At the heart of this project was the introduction of Digital Product Passports, powered by GS1 standards. Using GTINs, these digital labels ensured that tagged materials supplied by Natural Building Systems had a unique, standardised identifier. GTINs also allowed seamless integration across systems, ensuring that material data remained consistent, structured and easily accessible to all stakeholders. This proved to be a game-changer, eliminating fragmented record-keeping and enabling real-time, data-driven decision-making.

Digital Product Passports are set to become a cornerstone of sustainable construction. As regulatory pressures increase and industry stakeholders seek greater transparency, DPPs provide a structured, digital record of a product’s lifecycle, from raw material extraction to end-of-life reuse or recycling. By embedding DPPs powered by GS1 identifiers into the construction process, materials can be effectively managed, repurposed and reused, reducing waste and improving environmental outcomes. This approach aligns with circular economy principles, ensuring that valuable building components are not lost but instead reintegrated into future projects.

NBS products were GTINs that were embedded within RFID tags provided by Barcode Warehouse, as well as QR code powered by GS1 supplied by OrcaScan. These identifiers linked directly to the Circuland platform, where stakeholders could access a full picture of the material’s composition, sustainability credentials and lifecycle tracking. The integration of these technologies allowed for real-time visibility of materials, reducing waste and improving procurement accuracy.

With GTINs at their core, Digital Product Passports became the backbone of the project. They provided a structured way to document materials, ensuring compliance with sustainability regulations and simplifying future renovation or deconstruction efforts.

Instead of relying on scattered paperwork or proprietary systems, all relevant data was standardised and accessible through GS1’s globally recognised framework. RFID tagging further enhanced this by enabling site teams to quickly scan materials, retrieving critical information instantly and improving on-site decision-making.

The Impact

By structuring data through GS1 standards and GTINs, the project’s stakeholders had real-time access to consistent, accurate material information. Standardised data-sharing eliminated roadblocks, enabling architects, contractors and suppliers to collaborate more effectively. The result was greater efficiency, improved project timelines and stronger accountability across all phases of construction.

The use of RFID-enabled tracking reduced the need for manual checks, cutting delays and minimising the risk of human error. Unique material identifiers made reuse and recycling effortless, embedding circular economy principles into construction. By uniquely identifying materials with GTINs, products could be catalogued with complete lifecycle data, ensuring their responsible reuse instead of contributing to landfill waste.

The interoperable, digital-first approach introduced in this project is scalable and replicable and, beyond operational efficiencies, the sustainability benefits are profound. Construction and demolition waste accounts for a significant proportion of global landfill, but with GS1 powered tracking, materials can be effectively repurposed rather than discarded. GTINs ensure that these materials retain their identity and associated data, making it easier for the industry to truly embrace circular practices.

A blueprint for the future

At Old Newton Primary School GS1 UK standards and Digital Product Passports are demonstrating how interoperability, transparency and sustainability are the foundations of a smarter, more connected industry. The project has shown how digital technologies can transform construction, empowering businesses to build with confidence, track with precision and collaborate without barriers.

The success of this initiative paves the way for broader adoption of digital tracking solutions across the sector. As regulations tighten and sustainability expectations grow, businesses that embrace GS1 standards will be better positioned to meet future challenges.