July 04, 2016 Industry news

Andy Robson, our RFID expert, spoke at Drapers Digital Forum on how RFID enables you to become truly omnichannel

We all know that customers don’t shop channels, they only see brands and how best to buy the products they want. So, when apparel retailers talk about omnichannel, it’s really just about retailers catching up with customer expectations in the digital age.

At the heart of retail today is the need for retailers and brands to satisfy three key customer wants:

- What your customer wants

- Where they want to shop

- When they want it

To get there, retailers and brands have built responsive websites, mobile apps, better fulfilment options and added more choice overall. But are the three customer wants being fully satisfied yet?

In reality there’s a lot of disparity within the industry, with stories of good – and not so good – practice readily available. Crucial to the success stories is the ability to join the dots between the front end channels and the operational processes that service them. And I’m not talking systems integrations, I’m talking about something far more fundamental that’s at the core of retail – data. Put simply, retailers need to improve their product data and how they use it across their business.

Retailers need to be able to answer three questions with absolute confidence:

- What products do we have?

- Where are they located?

- How quickly can we get them to our customer?

Being able to answer these questions is vital if the silos that many retailers operate in today are to be broken down. A real-time and accurate answer to each of these questions is the only way for a retailer to gain complete visibility of their inventory, customer and business.

The real truth

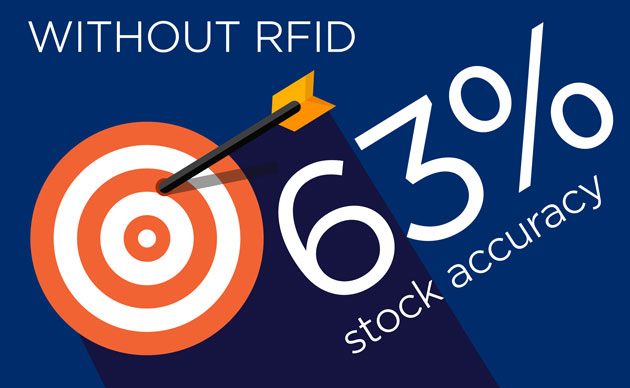

When it comes to products, a retailer’s stock records frequently don’t match what’s physically there – apparel retailers typically only have 63% stock accuracy.

Most retailers conduct a stock-take twice a year. However, due to theft and human error these records typically deteriorate by 2-3% per week, so after just a few weeks the data is no longer effective in informing business decisions. When 1 in 3 items may not be there, retailers are forced to make allowances for the data inaccuracies within their inventory records. It’s commonly believed among retailers that when their stock records reflect single units of a best seller in a handful of stores, chances are those items are no longer there.

This is why retailers typically operate with a buffer stock – a percentage of stock that is not made available online to safeguard against uncertainties in stock records. The item may not exist but if it does, it represents a missed sales opportunity and a customer that was unable to purchase the product they wanted.

The solution

In order to solve this issue retailers need access to accurate data in real time about their products. To do this there needs to be a shift in mind set: retailers need to stop thinking about SKUs and start thinking about items.

It’s no longer enough to consider how many of each style or size there is. To get the level of accuracy and the timeliness of information to fulfil the customer’s wants, retailers need to be storing data about and tracking each and every one of their products.

How to track such an enormous amount of data

How to track such an enormous amount of data

Knowing where every single product is at all times sounds like a mammoth task. Using traditional stock keeping methods it’s probably insurmountable.

So the obvious answer in the digital age is to automate it. And RFID is the technology to do this. – it’s the barcode for the digital age. By just waving a scanner up to 20,000 items can be counted in an hour – and you don’t just know how many of each style or size there is, you know every single item uniquely.

It’s this data capture magic that enables retailers and brands to know where each and every one of their products is, and enables access to that information exactly when it’s needed. It links the physical world of stock and operations management with the virtual world of systems and data trading.

How RFID helps deliver the customer wants

At a base level RFID allows quicker and more regular counting of stock, enabling weekly, daily or even ‘always on’ stock counting, and identifying the location of an item of stock much faster than other methods. The automation of processes stretches beyond stock taking, with shipping and receiving frequently being the next processes to be updated in an implementation.

But how does this help you to fulfil your three customer wants though? Well, with more information about where it is, stock can be given maximum exposure to customers – cutting out-of-stocks by up to 50% and helping retailers to sell more at full price.

RFID takes inventory accuracy from 63% to 95%. With this level of certainty and confidence in stock data, retailers can take deliver new levels of service to their customers, leveraging the full scale of their supply network – not just a particular channel.

You might be interested in

RFID (Radio Frequency Identification) - Getting to know each and every one of your products