What’s the difference between a static QR code and one containing dynamic data?

Static QRs are encoded with data that doesn’t change – typically just the GTIN (Global Trade Item Number) - meaning they can be incorporated as part of the artwork.

Dynamic QRs include additional data like expiry dates and batch numbers which change as often as the manufacturing process requires. As the QRs are constantly changing, they will need to be printed on the production line.

QR code powered by GS1 encoded with static data (GTIN)

QR code encoded with dynamic data (GTIN, batch and use by date)

Technology considerations

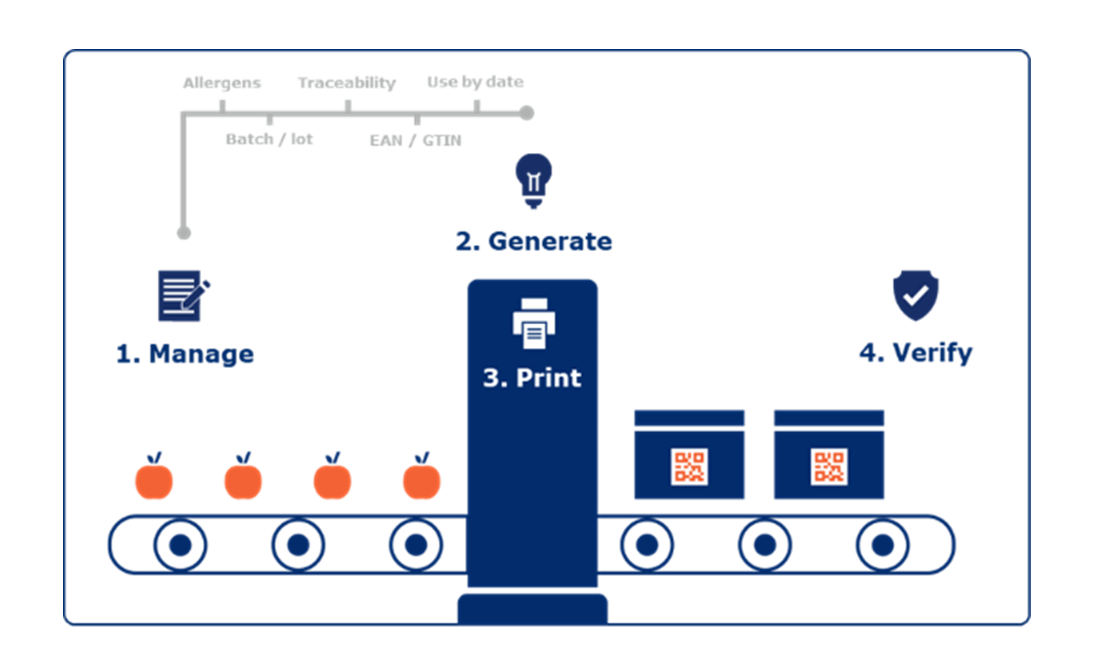

To implement dynamic QR codes, you might need to involve a few of your hardware and software solution providers, and your first step is to engage these people to understand your current readiness for printing 2D codes on pack.

- Manage - Suppliers will need to feed the data from their internal systems or ERP system to the software they use to generate the code.

- Generate - Data is then generated into a QR code using the relevant software, please check that the data you have encoded follows the GS1 Digital Link standard.

- Print - QR codes will need to be printed inline, please ensure you work closely with you print hardware supplier.

- Verify - Suppliers then need to verify the codes to ensure correct data is encoded and that the QR code is compliant with GS1 standards before anything is sent to store. This includes checking size, colour, placement and symbol quality.

We have a number of solution partners who specialise in QR solutions that utilise GS1 standards across the manage, generate, print and verify spaces. Check out the GS1 UK partner finder to find one that meets your needs.

Internal stakeholders to involve and typical timelines

Implementing dynamic QR codes typically takes between 3 and 9 months and involves multiple departments. Forming a project team comprising relevant stakeholders and initiating the exploration of options early in the process can facilitate coordination.

These are the key stakeholders that we have identified that often need to be involved:

- Technical

- Engineering

- Operations

- Commercial

- Packaging

- IT

- Procurement

- Research and development

How do I choose which product to start with?

Where possible, begin by selecting products packaged on lines with hardware and software that already has the capability to print 2D codes; then, consider these factors to decide which products to prioritise.

- Simple packaging formats - products with flat surfaces where you have enough space for the QR codes

- Slower production lines on which it will be easier to test

- Lines with limited distribution to enable you to contain any issues quickly

What are the common challenges?

Lots of things can impact the quality of your QR code speed, material, environment and even just the way the packaging is passed down the production line. Consistency in the quality of QR codes is key so we highly recommend having an inline verification that not only tells you that the data in the QR code is correctcorrect, but the quality is good enough to be scanned at POS

You may find that hardware in some cases might need to be upgraded but capture this as part of your futureproofing

When reviewing artwork ensure there is enough space to print a QR code

QR printing can wear down print heads faster as it’s a larger area to print so ensure you check them on a regular basis

QR code best practice

There are a few different elements that are important to get right when it comes to getting a compliant QR code on pack, including:

In the GS1 UK knowledge hub we have provided lots more useful information to ensure you get your QR code right.

5 tips for success

Engage with GS1 UK

- If you have any questions, please reach out to us on QR@gs1uk.org.

- Send in samples if you'd like us to review them for compliance and quality.

Get the basics right

- Create a test label format early to build foundational understanding.

- Ensure the overprint area is matte white and opaque to maintain scan contrast.

Check your equipment

- Review current machinery and software for compatibility.

- Confirm the ability to print QR codes at the required minimum size (e.g. 16mm x 16mm) and position (e.g. front of pack).

Understand how different material performs

- Cardboard is generally easier to print on than heat-seal film.

- Be prepared for more frequent print head cleaning and maintenance.

Plan for long-term robustness

- Establish a centralised database for dynamic data by product line.

- Implement 100% end-of-line verification to ensure ongoing print accuracy and readability.

GS1 UK is looking to setting up a supplier working group to share learnings, challenges, and practical tips around QR implementation. It’s a great chance to hear what others are doing and swap ideas.

If you’re interested in joining, just drop us an email at QR@gs1uk.org with the subject line “Supplier Working Group” – we’ll be in touch with more details.