Why product identification matters

Every construction project involves thousands of products sourced from different suppliers. When products are recorded under inconsistent names or recorded under different identifiers across systems, problems quickly arise:

- Inconsistent and unreliable product information: The same product can appear under different names or codes across suppliers and systems, making it hard to know what’s correct (e.g. two “different” items that turn out to be the same product). This also leads to data errors, mismatches and duplication across systems.

- Hard to verify authenticity or match product data: When product information moves between companies and platforms, details often get lost or changed, making it hard to confirm authenticity (e.g. unsure if a delivered item is the real certified product) or to match data across systems.

- Procurement and supply-chain inefficiencies: Buyers struggle to ensure they’re ordering the exact specified material because product data isn’t aligned (e.g. materials arriving that don’t match the design spec or approval). This can slow down projects and create costly rework.

These problems cost time, money, and, in some cases compromise safety. With regulations such as the UK Building Safety Act, the need for reliable, standardised product identification and transparent data is stronger than ever.

What is a GTIN

A Global Trade Item Number (GTIN) is a unique, globally recognised identifier for trade items. It works like a product’s digital fingerprint, providing a consistent way of identifying products worldwide and is allocated according to GS1 standards, ensuring global consistency and compatibility.

GTINs can:

- Work with GS1 barcodes, QR codes and EPC-enabled RFID tags (e.g. QR on plasterboard sheets, RFID tag on cable drums)

- Integrate into procurement systems and ERP platforms.

- Ensure one product equals one identity everywhere

What does the GTIN look like

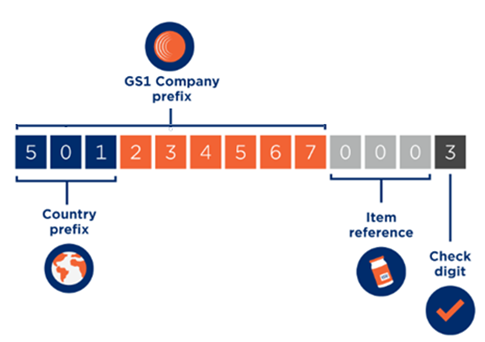

A GTIN serves as a unique identifier for a product. These numbers, often referred to as ‘barcode numbers’, ‘EANs’ or ‘UPCs’ are commonly found beneath barcodes on products worldwide.

GTINs can be found in over 20 sectors including retail and healthcare.

In the UK and Europe, GTINs typically consist of 13 digits, while in the US, they’re 12-digits long. Shorter 8-digit numbers are also part of the GTIN family and are used to identify smaller products. Different packaging levels, such as cases, can also be identified by GTIN-14s.

GTINs are licensed from GS1 organisations globally. Licencing numbers ensures their uniqueness and means they can be traced back to the brand owner. If GTINs are obtained from any other source, you may experience problems with your trading partners, major retailers and marketplaces such as Amazon.

Why the GTIN matters in construction

Construction projects rely on thousands of products that often look alike but differ in safety, compliance or performance. GTINs provide globally unique product identities that can support clearer information flow across systems and reduce the common issues seen on sites and in procurement, such as inconsistent codes, mismatched data, and difficulty verifying authenticity.

- Compliance: GTINs can help ensure products are correctly identified for UK Building Safety Act, CPR and UKCA/CE requirements. This reduces confusion between similar items and can make it easier to trace or remove unsafe products. GTINs can also be used within QR codes to connect products to trusted digital information (e.g. certification databases, Digital Product Passports).

- Digitalisation: GTINs offer a single, globally standardised identifier that works across sectors, systems and tools. This can support cleaner data exchange (e.g. between ERP systems), reduce mismatches when product data is shared, and give workers quick access to manuals, warranties and performance data through QR scanning.

- Sustainability: GTINs can support circularity by linking products to EPDs, recycling instructions and reuse information, and they help maintain consistent lifecycle data across the supply chain. They can also support ESG reporting by connecting sustainability information directly to the product identity.

Together, these points show how GTINs can strengthen consistency, transparency and trust in construction product data.

Benefits for stakeholders

Because GTINs are globally unique and long-lived identifiers, they offer reliable benefits for many players in the supply chain, helping each group avoid data errors, reduce rework, and improve safety and compliance checks.

- Manufacturers: GTINs can provide a single, standardised identity for each product, preventing mix-ups with similar items. This supports compliance (e.g. ensuring the right fire-rated door is identified), helps digitalisation through consistent data in procurement systems, and links product information to sustainability data such as EPDs.

- Contractors: GTINs can reduce errors onsite by making product identification clearer across labels, QR codes and installation checks. They can also support traceability through links to pallet IDs or batch numbers when tracking materials for recalls or defects. GTINs can help integrate data with mobile apps and site-management software to streamline tasks.

- Clients/building owners: GTINs can give confidence that installed products are correctly identified and traceable. They can support safety checks (e.g. verifying cladding or fire doors), provide easier access to manuals and warranties, and enable links to product passports and reuse/recycling information.

In practice, GTINs can help each stakeholder work with clearer, more consistent product data, reducing risk and improving decision-making across a project’s lifecycle.

GTINs in action: From product ID to full traceability

A GTIN on its own is just a number, but when carried on products and linked to data, it unlocks the ability to identify, track, and trust every item across the construction supply chain.

- GS1 data carriers: Put GTINs on products so they can be scanned anywhere. They can be placed in barcodes for simple, low-cost, everyday items (e.g. a bag of cement), QR codes for instant access to online information like manuals or certificates (e.g. printed on a window frame), and RFID tags for automatic, contactless tracking in bulk or harsh environments (e.g. on a cable reel).

- Other GS1 identifiers: GTINs can be combined with batch or serial numbers for greater precision for example (e.g. a fire door with a unique serial number, or a cable drum linked to a production batch). For fixed or returnable assets, identifiers like GIAI (Global Individual Asset Identifier) or GRAI (Global Returnable Asset Identifier) can also be used respectively (e.g. a tower crane with a GIAI, or a reusable pallet with a GRAI). For logistics units such as pallets or containers, the SSCC (Serial Shipping Container Code) provides a unique ID (e.g. a pallet of plasterboard).

- GS1 EPCIS (Electronic Product Code Information Services): a GS1 standard that shares events linked to a product: what happened, when, why, where and how (e.g. a door manufactured on 1 June, delivered to Site A on 5 June (via RFID scanning), and installed on 10 June).

Together, these elements create a digital thread of traceability: a complete product history, from manufacture to installation, use and end of life.

How to start using GTINs

Implementing GTINs is straightforward. Organisations can:

- 👥 Become a GS1 Member: Join GS1 to begin allocating GTINs to all your products, ensuring global standardisation from the start.

- 🔄 Apply GTINs Consistently: Use GTINs across all suppliers and product ranges to maintain clarity and consistency.

- 📱 Make GTINs Scannable: Implement GS1 barcodes, QR codes, and RFID tags so GTINs can be easily scanned on site for efficient identification.

- 🌐 Publish GTINs Online: Display GTINs on your product webpages to provide customers and partners with trusted, accessible product data.

- ⚙️ Integrate GTINs with Systems: Embed GTINs into your ERP and other workflow platforms for seamless, automated processes.